Zen

Lasercut Acrylic Cup Accessory

How might I design a beverage accessory that is missing from my daily routine using only acrylic sheets?

Description

Designed, fabricated, and assembled a lasercut acrylic cup holder prototype that fulfilled the functional and design requirements for the solution I had developed:

-

Provide a sleeve or barrier to prevent burns from holding a hot drink

-

Provide a ventilated place to store used tea bags

-

Provide a surface to hold the lid to keep it sanitary

-

Be portable so it can be easily carried

The project, Zen, is named after my favorite green tea, Tazo's "Zen".

Details

Tools & Processes: concept mapping / mood boards / sketches / rapid prototyping / foam core modeling / heat forming / laser cutting / SolidWorks

Overview

An individual graduate-level class project designed to test each students' creativity in designing a drink accessory that is useful to them in their daily routine while applying the constraint of only using lasercut acrylic sheets.

Tea Drinking Discovery & Pain Points

A concept map was created to identify the pain points in my personal daily tea drinking experiences.

Teabag needs to be removed to prevent bitter tea. However, there is nowhere to dispose of it nearby

Used sugar packets need disposal

Removal of lid to allow drink to cool. But there is no place to set the lid other than an unsanitary table or counter

Using a single-use cardboard sleeve for protection from a hot paper cup produces unnecessary waste

Tea Moodboard Inspiration

A moodboard was created to inspire the design aesthetics and form of this product.

The collage of photos depict the situations I face with used tea bags and no place to dispose of them, tea that is too hot, wasteful corrugated sleeves, lids being propped up against the cup to inevitably fall, and tea getting bitter if the teabag is not removed in time.

Functional Requirements for Cup Accessory to Improve Tea Drinking Routine

The following were the functional and design requirements derived from the pain points. The product must:

Hold a used tea bag and any residual liquid

Provide a layer in between where a hand touches the cup's outer surface to prevent burns

Provide a surface or receptacle for the lid so it does not need to be placed on an unsanitary surface

Fit into a cup holder or backpack pocket as a single entity

Hold small pieces of trash, such as a sugar packet wrapper

Cup Accessory Form Exploration

Methods for shaping acrylic were researched, sketched and tested with rapidly prototyped, low-fidelity models.

Rapid Prototyping

Kerfing (a pattern lasercut into material to make it bendible), interlocking finger joints, and heat forming methods were investigated.

It was concluded from these initial prototypes that a single locking mechanism (L-lock as pictured below) was too fragile and a panel design was too large and cumbersome.

Foam-core test model

Delicate locking mechanism

Lasercut test pieces

Panel prototype

Sharp edges

Additional Ideation with Bendable Acrylic

The next iterations were tests to see if kerfing patterns could result in bendable pieces of acrylic that could curve around the cup and form the bottom container for the tea bag.

Even with the kerfing, the acrylic was not nearly bendable enough. Along with added support rails on the kerfing and heat forming as seen in the images to the left, the structure of the plastic was too fragile and difficult to manipulate.

Insights derived from tests:

Acrylic is extremely brittle and cannot be expected to act like wood

Heat forming with kerfing is not stable for forming because it easily warps

With a test piece, heat forming works well with small uncut, solid pieces of acrylic sheets

Acrylic should be used to its advantage (brittle strength)

First kerf pattern

Kerf warping

Zen 1.0

The final design as seen in the sketches below.

-

Single piece of heat-formed acrylic

-

Twist on/off teabag compartment

-

Taking advantage of acrylic's brittle characteristics

SolidWorks Assembly Model rendered in Keyshot for Proof of Concept

First Iteration Assembly Process

Second Iteration Assembly Process

Zen 2.0

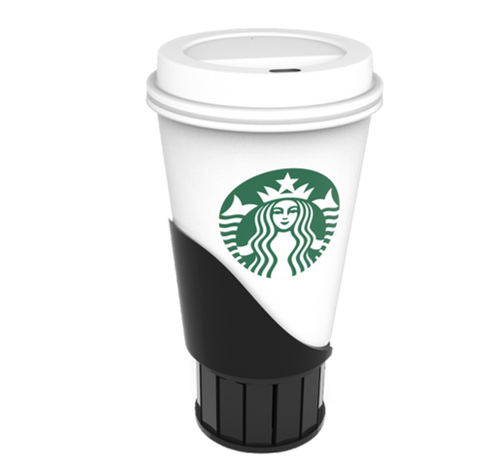

The final version of acrylic cup holder prototype was fabricated.

The laser cutter tolerances were adjusted and accounted for, heat forming was performed very meticulously so there would be no cracking, and the panels were assembled carefully.

Final Prototype Assembly

Zen 2.0 Demonstration

Zen 2.0 "Cute-Tea" Engraving and Hand Heat Protector

Conclusions & Next Steps

There were a lot of unexpected challenges that arose during this project. I learned a lot about acrylic's properties and detailed, high tolerance work. In the end, I was able to create a tea cup accessory that meets all of my functional requirements:

-

Sleeve acts as barrier to prevent burns from holding hot drink without producing unnecessary waste

-

Ventilated compartment to place used tea bags and/or sugar packets

-

Provides clean surface to hold lid

-

Forms single, portable entity

Further development refinements would include making the locking mechanism more durable and refining the cup side sleeve aesthetics.